MASTER EVO 90 / MASTER EVO 180

MASTER EVO to machine the part on multiple sides halving the cycle time

- Reliable since using the same groups Master 1 and Master 2

- Flexible since it is configured for 4/5 axis indifferently with axis A or B

- Productive since the two electrospindles machine the part at the same time

It is equipped with two 90° or 180° spindles which can operate at the same time on the same part, each one provided with its own 32 tools ATC.

> Recommended for:

- Very complicated parts which require a high number of tools

- Parts which have different operations at 90° between them or symmetrical

- Parts with long tool replacement time compared with the machining time; the two spindles can operate in sequence, reducing the tool replacement time to zero

> Complete Turning

On one of the two spindles it is possible to flange a Komet head PKE 250 for difficult turning operations and in hidden time

> Axis module

The “Axis module” is made of a “box in box” module with axis translation on hardened guides by means of recycle runners, ball screws and axial brushless servomotors. Positions controlled by axial digital transducers. Electrospindle 25 kW or 47 kW depending on the material to be machined

> Tool changer

Master is provided with ATC system, an Automatic Tool Changer process consisting of three groups: rotating disk magazine with tool holder and collet support arm with automatic lock, both manufactured by DVK System, and a rotation/extraction group with cams. The disk is random bidirectional controlled by brushless servomotor.

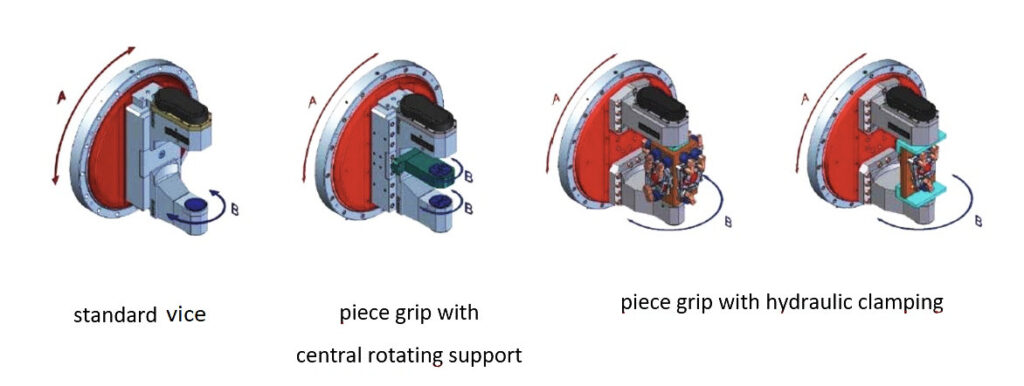

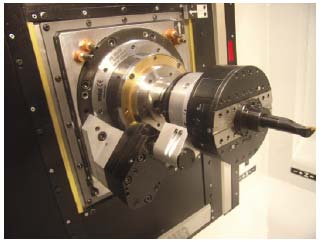

> Part grip vice

The heart of Master is the two jaws self centering vice, with parallel closure by oil hydraulic cylinder and stroke 25+25 mm. The whole group is lubricated by grease and pressurized air/oil. Satellite with self-centering vice rotation “axis A” and jaws rotation “Axis B”, controlled by brushless servomotors placed outside the vice space. 360.000 divisions on both axis with continuous rotations and oil hydraulic lock. The optional central turning support allows to close two overlapping pieces. In alternative, it is possible to “clamp” the piece with hydraulic devices..

> U-Turning

CNC turning head

(mod.TA-125 D’Andrea and KomTronic UAS115) Innovative solution for internal and external turning, glass runs, conical borings (even variable ones), concave convex radius, cylindrical and conical threads, phonographic spirals, etc. The tool holder slide feed is controlled by an axis of the machine CN.

Option

> Prefilter and single centrifuge exhaust fan

> Chip conveyor with plates or dragging chain, with or without rotofilter

> High pressure coolant feed inside the spindle

> Automatic life tool treatment

> Cut current control associated to the life cycle of the tool

> Tool length and diameter presetting laser photocell

> 3D tracer point RMP60 for remote part reset and measurement

> Automatic offset of X,Y,Z axis thermal drift